Below are the questions asked during the live event, along with their respective answers.

Q: Can off the shelf filters be used as COTS filter?

A: Because of the stringent military environmental applications it is not recommended to use OTS filters. Most OTS filters mechanical packages are not fully welded, therefore a) moisture and dust can get into the filter package, b) they might not withstand shock and vibration tests required by military standards.

Q: Do the COTS filters need to be UL certified?

A: COTS filters are designed for military applications and military in most cases does not require filters to be UL listed or recognized.

Q: What is the maximum leakage current for military standards?

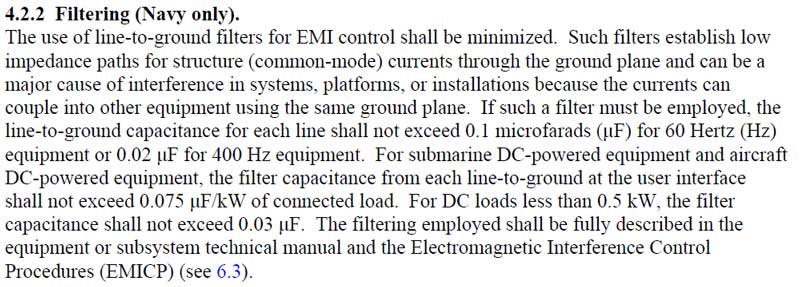

A: Following is the line to ground capacitance as specified in MIL-STD-461;

Q: During the tuning how are you adding components to the sealed unit or are you adding them in series

A: The tuning of a sealed filter is only done by adding filter components to the input and/or output terminals. If that is not sufficient an open frame prototype filter is recommended for tuning and changing filter components during EMI conducted emissions test.

Q: Is the ambient noise test necessary in case of conducted emission test, as I think that it is required for radiated emission only?

A: Ambient noise test is also recommended conducted emission test to make sure power coming into the shielded room is clean and it is below the limit line with a great margin.

Q: What is importance of 150kHz value in filter design?

A: The 150 KHz is specified by European standards. The 150 KHz could be important because of numerous smart products that are designed to communicate at or around that frequency.

Q: Is the conducted emission test performed at signal lines also?

A: EMI requirements are application dependent and it can apply to signal lines depending on power input to the equipment.

Q: What value of diff inductor works around 23kHz

A: The value of the DM coil is selected based on the noise levels at or around 23 KHz; the higher the noise levels the higher the DM coil inductance value. Unlike the CM coil the DM coil has to withstand the line current w/o saturation so the higher the current the lower the inductance value. It is recommended the DM coil to be used with an X capacitor in order to reduce the DM coil inductance value. With all said an inductor between 50uH to 350uH should help reducing the DM noise at or around 23 KHz.

Q: Some note about proper direction/orientation of filter installed?

A: See answer to next question.

Q: Does it matter what the load vs source orientation is for the COTS filter? i.e. can you connect the filter in any direction?

A: Filters in general are bi-directions. It is recommended, if;

a) The load is inductive; choose a filter with capacitor at the output of the filter.

b) The load is capacitive: choose a filter with a coil at the output of the filter.

Q: Do you know of a good quiet 400Hz lab power supply (into the chamber from outside chamber)?

A: I wish I could say yes. To be fair most power supplies are tested for EMI in a 50 ohm system and equipped with an EMI filter. This does not mean the power supply will provide clean power with any complex load.

Q: Why there is not found a built-in differential mode inductor in the filter design?

A: Off the shelf filters seldom have DM coils designed into the filter circuit; a) because in commercial world conducted emissions measurement starts at 150KHz therefor there is no need for DM coils. b) DM coils depending on product current rating could be large in size which will make the filter size large and expensive to be readily available from stock, but they can be ordered as required.